LODEN

A fabric with a long history

Loden - Natural functionality

Loden - natural and functional, for Hunting & Leisure. This first-class natural material and high-quality woollen fabric has been impressing hunters for generations with its robustness, durability and quietness.

The origin

Loden is a collective term for woven woollen fabrics. The wool comes either from Austrian mountain sheep (somewhat rougher) or from Australian or New Zealand merino sheep (soft and cosy). The exact origin of the word Loden can no longer be clarified today. What is certain, however, is that loden cloth already existed in the Middle Ages and is practically the first known functional fabric.

Two factors make Loden a unique product:

- the natural properties of sheep's wool

- the special processing of the wool

Sheep's wool is naturally equipped with wind and water-repellent, warming and generally climate-regulating properties, enabling the sheep to be outside in the great outdoors in all weathers. Its climate-regulating properties prevent the animal from cooling down.

These good properties are the basis that Loden utilises as a fabric. They are further enhanced by the way in which the outer fabric is processed.

What exactly is Loden?

Loden is traditionally made mostly from "conventional" new wool, either from mountain sheep from the Alpine region or from merino sheep, as already mentioned in the origin. However, precious hairs, such as alpaca or cashmere wool, can also be easily processed into loden fabrics.

The manufacturing process creates different layers that optimise the properties of the wool.

From wool to yarn

Spinning

The first step in the production of loden fabric is spinning the yarn from the raw wool. Due to the varying thickness and density of the yarn, different fabrics are produced. Depending on the type of loden, a thicker or finer yarn is used.

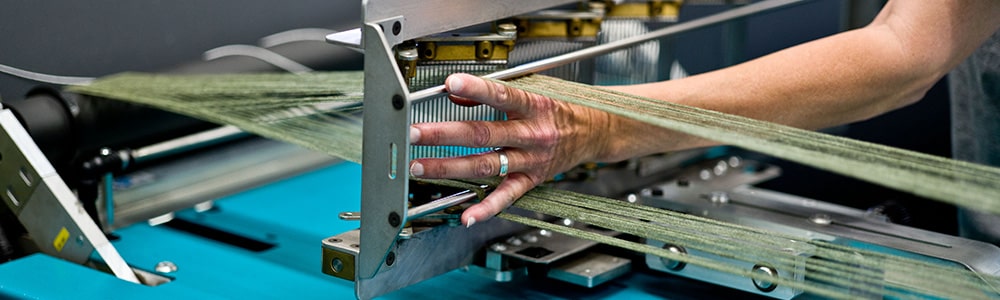

Weaving

The next step is weaving. In this process, the spun yarn is woven into a dense fabric and the type of weaving influences the weight, density and stability of the final fabric. Compared to knitted fabrics, a woven fabric is much more dimensionally stable, but less elastic.

The walk

Now comes the decisive step - fulling. The surface becomes matted through the use of water and heat as well as the mechanical action. The result of this step is that the Loden shrinks by up to 30% in both the warp and weft directions. The result is a more or less even surface that seals the homogeneous structure of the original fabric.

The outer felted layer serves as natural protection against wind, water and dirt. The inner fabric provides the necessary stability and the trapped air in the gaps ensures a pleasant insulating effect.

Refinements

The basic properties of the Loden can be extended or reinforced depending on the area of application. Various finishing options are possible.

The fabric is now roughened by machine with rollers, making it soft and supple. In the early years of Loden manufacture, dried thistles were used for this process. Once the fabric has been roughened, it is placed in the shearing machine, where the roughened fibres are cut off evenly.

The length of the "fluff" varies depending on the area of application: very short for clothing fabrics and longer for blanket fabrics, so that the cosy and soft character is retained. The next step now takes place in the decatising machine. Here, the type of finishing (equipment) varies depending on the area of application: for clothing fabrics, more pressure and hot steam are used to make the outer fabric more dimensionally stable. In the case of blanket fabrics, no pressure is applied and only hot steam is used to maintain the fluffy character of the fabric.

Properties of Loden

-

Water-repellent

Due to elaborate processing of the new wool (fulling) -

Breathable

New wool is very breathable, it absorbs water vapour from the body and releases it to the surface of the fabric. -

Temperature equalising

The structure of the fabric enables regular heat equalisation. Loden does not let the cold through and retains body heat. -

Resistant to dirt

Due to the wool lanolin, new wool is dirt-resistant. Dirt and grime can simply be brushed off the Loden when dry.

-

Odour-inhibiting

The advantage of wool over conventional synthetic fibres is its ability to neutralise odours, which means that synthetic fibres often have to be washed after being worn once. With Loden, a simple airing is enough to get sweat and similar odours out of the fibres. -

Flame retardant

Due to its natural protein content, Loden is significantly less susceptible to flying sparks and fire compared to synthetic fibres. This makes it significantly less flammable. -

Moisturising

The wool fibre can absorb up to a third of its own weight in water without feeling wet. The moisture is absorbed by the fibre and slowly released again.

The raw material

Loden is traditionally made from virgin sheep's wool, which today comes mainly from countries such as Australia/New Zealand, South Africa and South America, as the wool from these countries is softer due to special breeds of sheep and the prevailing climate. On the following pages, we will introduce you to the most popular types of wool, including wool from mountain sheep, merino sheep, alpacas, Angora rabbits and cashmere goats.

Naturally good wool

Despite intensive efforts and trials, the chemical industry has not yet succeeded in artificially recreating sheep's wool with its positive properties.

Mountain sheep </h4

The special thing about mountain sheep's wool is that it is sourced from local farmers in the Alpine region. The animals are shorn twice a year before and after the alpine season. Loden made from mountain sheep's wool is very robust and hard-wearing, which is precisely why the quality is so popular with hunters. Whether it's work trousers, a weather patch or a classic jacket - mountain loden is the perfect choice.

Merino

The animals originally come from the North African plateaus of the Atlas Mountains and are now one of the oldest and hardiest sheep breeds in the world. Merino sheep lived there under extreme, often adverse weather conditions that can only be found in the mountains, where they spend all four seasons in a row. The wool of the Merino sheep is particularly fine and elastic. It yields between two and three kilograms of the finest quality wool per year. The wool now comes mainly from Australia, New Zealand and South America.

Alpaca

The fine hair of the humpless sheep camels native to the Andes is one of the most valuable and softest natural fibres of all. Alpaca wool is known for its particularly heat-regulating properties. The hair is hollow on the inside and can therefore store body heat better than any other quality of wool. Because it also has very little wool grease (lanolin), alpaca wool is particularly suitable for Allergens as it prevents bacteria from multiplying and dying off.

Noble hair

Fine hairs are particularly high-quality animal hairs that do not come from sheep, such as the wool of the Angora rabbit and the cashmere goat. These wool qualities are characterised by their special fineness and softness. Angora wool is not only the softest and has a particularly fluffy touch, it is even said to have a healing effect due to its warming and sweat-absorbing properties. Cashmere wool is the fine undercoat of the goat. The cashmere goat has adapted to the extreme climatic conditions in China, Mongolia, Iran and Afghanistan. Their woollen coat is particularly thick, as they live in harsh conditions at an altitude of around 4000 metres at temperatures of up to minus 40 degrees.

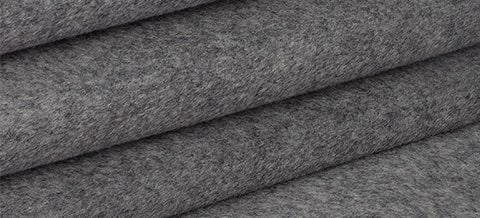

Stroke loden (sheathed loden)

Stroke loden is a subspecies of Loden that is characterised by special quality features. The term "Stroke Loden" is derived directly from the work step by which it is produced - the so-called stroke roughening. This involves roughening or combing the right side of the fabric using special tools such as steel scrapers and/or natural thistles. The end result is a fabric with all the fibres pointing in one direction and lying evenly on top of each other. On closer inspection, the roughened fabric layer is therefore reminiscent of closely laid roof tiles.

In addition to the particularly fine sheen, which is also known as lustre, the roughening also has the effect that the tight fibre bond allows rainwater to bead off particularly well and thus provides optimum protection against moisture. An additional impregnation further enhances this effect. Stroke loden does not need to be permanently cleaned.

Because of the beading effect, it is sufficient to simply allow the garment to dry after the rain. Loden clothing is generally very easy to clean and regular airing is usually sufficient. If dirt does need to be removed, brushing or dabbing with a damp Wraps & shawls is often sufficient. This saves energy and water and thus protects the environment.

Because of all these properties, knitted loden is very popular for outdoor clothing.

Walk

In contrast to the classic cloth loden, fuller's wool is not woven but knitted and then felted. The advantage of this is that it is more elastic, but the disadvantage compared to woven Loden is that it is less windproof and waterproof. Strength and dimensional stability are also lower than with woven loden fabric.

Mountain/mountain loden

Mountain loden has a rustic character and is made from coarser wool from the Alpine region. Heavy work jackets and coarse coats are mainly made from mountain loden.

Welsh loden

This Loden is also called diagonal Loden. The warp has a different colour than the weft, so the twill weave is very visible.

Cloth loden

Cloth Loden is a heavily felted Loden, it is not napped and therefore has a smooth surface. It is mainly used for the manufacture of skirts, trousers, suits and costumes.